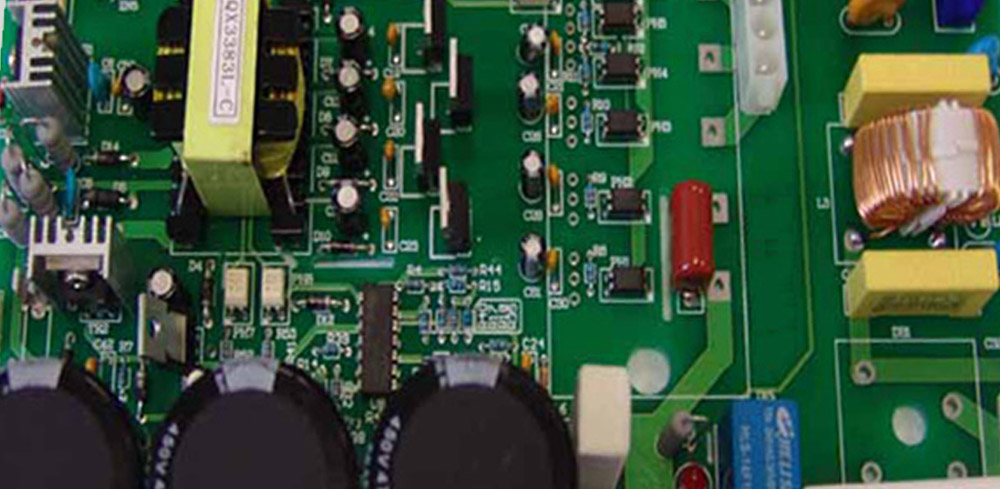

STL offers plated-through-hole assembly services for both lead-free and leaded printed circuit board assemblies. Our wave soldering stations support the manufacturing of both Rohs and non-Rohs product. Manual insertion lines can be setup quickly for prototype & low to medium volume PTH assembly. Whilst we will guide you through the quickest possible route to market, we will never allow speed of service to compromise quality.

PCBA's capabilities |

Finish |

Choices of various PCB finishes: OSP, Electroless Nickel Immersion Gold, HASL, etc. |

Secondary Operations |

SMT, DIP, BGA, Bonding available in process |

Smaller Component Size |

0201 package component |

Board Size |

Maximum: 460mm x 330mm |

No. Of Layers |

Up to 8 layers |

Conductivity Materials |

Gold, Tin and Bare Copper |

Max Speed of SMT Line |

0.09 second per chip |

Maximum Points per Hours |

36000 pcs per SMT Line |

SMT Line Production Capability |

5,500,000 pcs components per day |

DIP Line Production Capability |

384,000 pcs components per day |

Rework |

De-population and Re-population |

Services We Provide |

Surface Mount Technology - 9 Fully automated SMT lines |

Through Hole Technology - 2x15M two-way sitting Lines |

Ball-Grill Array Technology |

QC Process & Certifications |

RoHS ready and UL approved |